YE4 series three-phase asynchronous motor

Category:

YE4 series three-phase asynchronous motor is a fully enclosed, self-fan-cooled, continuous working single-speed motor developed by our company. The motor adopts advanced design concept: mature and precise processing technology; high-quality high-end raw materials, with compact structure, high energy efficiency, low noise, low vibration, stable and reliable operation, long service life and so on. As a driving equipment is widely used in all kinds of fans, pumps, machine tools and other equipment.

- Description

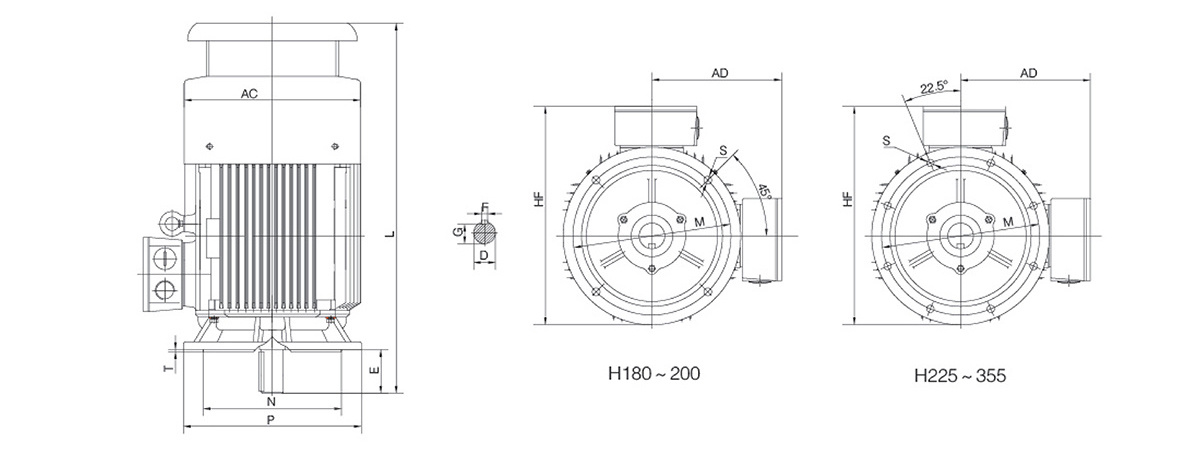

- Installation and external dimensions

- Electrical parameters

-

- Commodity name: YE4 series three-phase asynchronous motor

YE4 series three-phase asynchronous motor is a fully enclosed, self-fan-cooled, continuous working single-speed motor developed by our company. The motor adopts advanced design concept: mature and precise processing technology; high-quality high-end raw materials, with compact structure, high energy efficiency, low noise, low vibration, stable and reliable operation, long service life and so on. As a driving equipment is widely used in all kinds of fans, pumps, machine tools and other equipment.

YE4 series three-phase asynchronous motor is a fully enclosed, self-fan-cooled, continuous working single-speed motor developed by our company. The motor adopts advanced design concept: mature and precise processing technology; high-quality high-end raw materials, with compact structure, high energy efficiency, low noise, low vibration, stable and reliable operation, long service life and so on. As a driving equipment is widely used in all kinds of fans, pumps, machine tools and other equipment.

The efficiency of YE4 series three-phase asynchronous motor meets the requirements of level 2 energy efficiency in the GB18613-2020 standard, and can meet the IE4 efficiency level in the IEC60034-30 standard.

Main performance

● Rated power range: 0.12-375kW;

● Rated frequency: 50Hz;

● Rated voltage: 380V;

● Number of motor poles: 2, 4, 6, 8, 10, 12, 16;

● Standard protection grade: IP55;

● Insulation system: designed according to Class F (155 ℃), the temperature rise of the motor shall be assessed at 80K during rated output and direct power supply, and the temperature rise of the 2 and 4 poles of the 315 seat number and the motor of the 355 seat number shall be allowed to reach 105K;

● Motor cooling method: the standard cooling method is IC411 self-fan cooling, which can be a fan at the N end (non-shaft extension end) of the motor. Under the condition of meeting the cooling air volume, it can also be cooled by the wind brought by the fan driven by the shaft extension end;

● 2-pole motors with frame numbers 200 and above, motors with frame numbers 315-355 are equipped with oil injection nozzles as standard, and motors with frame numbers 132 and above are optional;

●Casting material: cast iron;

● Standard installation structure type: IMB3, IMB5, IMB35, etc;

● The motor can choose PTC or PT100 thermistor for winding protection, and can also be equipped with winding temperature measuring device. For motors above 160, bearing temperature measuring device can be selected;

● Special design: Our company can design special voltage and frequency motors according to customer requirements; IP65 protection and H-class insulation motors can be designed according to customer requirements; the appearance color of the motor can be adjusted according to customer requirements.

-

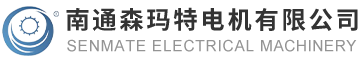

IMB35 H80~355

Seat Number Flange No. Number of poles Dimensions mm A AA B C D* E F G H K AB AC AD HD L BB HA LD Flange

Number of holesM N * P R * S T 80 FF165 2、4、6、8 125 34 100 50 19 40 6 15.5 80 10 165 167 145 220 305 142 12 72 4 165 130 200 0 12 3.5 90S FF165 2、4、6、8 140 36 100 56 24 50 8 20 90 10 180 190 170 265 360 180 12 76 4 165 130 200 0 12 3.5 90L FF165 2、4、6、8 140 36 125 56 24 50 8 20 90 10 180 190 170 265 390 220 12 76 4 165 130 200 0 12 3.5 100L FF215 2、4、6、8 160 40 140 63 28 60 8 24 100 12 205 206 180 270 435 233 14 83 4 215 180 250 0 14.5 4 112M FF215 2、4、6、8 190 45 140 70 28 60 8 24 112 12 230 235 200 310 440 216 15 87 4 215 180 250 0 14.5 4 132S FF265 2、4、6、8 216 55 140 89 38 80 10 33 132 12 270 296 230 350 510 226 18 99 4 265 230 300 0 14.5 4 132M FF265 2、4、6、8 216 55 178 89 38 80 10 33 132 12 270 296 230 350 550 256 18 99 4 265 230 300 0 14.5 4 160M FF300 2 254 65 210 108 42 110 12 37 160 14.5 320 335 265 425 670 315 20 146 4 300 250 350 0 18.5 5 FF300 4、6、8 254 65 210 108 42 110 12 37 160 14.5 320 335 265 425 670 315 20 146 4 300 250 350 0 18.5 5 160L FF300 2 254 65 254 108 42 110 12 37 160 14.5 320 335 265 425 710 355 20 146 4 300 250 350 0 18.5 5 FF300 4、6、8 254 65 254 108 42 110 12 37 160 14.5 320 335 265 425 710 355 20 146 4 300 250 350 0 18.5 5 180M FF300 2 279 70 241 121 48 110 14 42.5 180 14.5 320 365 285 460 735 359 22 161 4 300 250 350 0 18.5 5 180L FF300 4、6、8 279 70 241 121 48 110 14 42.5 180 14.5 355 365 285 460 735 359 22 161 4 300 250 350 0 18.5 5 FF300 4、6、8 279 70 279 121 48 110 14 42.5 180 14.5 355 365 285 460 770 394 22 161 4 300 250 350 0 18.5 5 200L FF350 2 318 70 305 133 55 110 16 49 200 18.5 395 418 325 525 870 454 25 186 4 350 300 400 0 18.5 5 FF350 4、6、8 318 70 305 133 55 110 16 49 200 18.5 395 418 325 525 870 454 25 186 4 350 300 400 0 18.5 5 225S FF400 4、8 356 75 286 149 60 140 18 53 225 18.5 435 465 350 575 880 431 28 189 8 400 350 450 0 18.5 5 225M FF400 2 356 75 311 149 55 110 16 49 225 18.5 435 465 350 575 885 466 28 189 8 400 350 450 0 18.5 5 FF400 4、6、8 356 75 311 149 60 140 18 53 225 18.5 435 465 350 575 915 466 28 189 8 400 350 450 0 18.5 5 250M FF500 2 406 80 349 168 60 140 18 53 250 24 490 525 405 655 990 515 30 207 8 500 450 550 0 18.5 5 FF500 4、6、8 406 80 349 168 65 140 18 58 250 24 490 525 405 655 990 515 30 207 8 500 450 550 0 18.5 5 280S FF500 2 457 85 368 190 65 140 18 58 280 24 550 588 435 705 975 510 35 215 8 500 450 550 0 18.5 5 FF500 4、6、8 457 85 368 190 75 140 20 67.5 280 24 550 588 435 705 995 510 35 215 8 500 450 550 0 18.5 5 280M FF500 2 457 85 419 190 65 140 18 58 280 24 550 588 435 705 1015 550 35 215 8 500 450 550 0 18.5 5 FF500 4、6、8 457 85 419 190 75 140 20 67.5 280 24 550 588 435 705 1035 550 35 215 8 500 450 550 0 18.5 5 315S FF600 2 508 120 406 216 65 140 18 58 315 28 635 620 555 870 1200 570 45 257 8 600 550 660 0 24 6 FF600 4、6、8 508 120 406 216 80 170 22 71 315 28 635 620 555 870 1230 570 45 257 8 600 550 660 0 24 6 315M FF600 2 508 120 457 216 65 140 18 58 315 28 635 620 555 870 1310 680 45 257 8 600 550 660 0 24 6 FF600 4、6、8 508 120 457 216 80 170 22 71 315 28 635 620 555 870 1340 680 45 257 8 600 550 660 0 24 6 315L FF600 2 508 120 508 216 65 140 18 58 315 28 635 620 555 870 1310 680 45 257 8 600 550 660 0 24 6 FF600 4、6、8 508 120 508 216 80 170 22 71 315 28 635 620 555 870 1340 680 45 257 8 600 550 660 0 24 6 355M FF740 2 610 120 560 254 75 140 20 67.5 355 28 730 710 655 1010 1490 750 52 284 8 740 680 800 0 24 6 FF740 4、6、8 610 120 560 254 95 170 25 86 355 28 730 710 655 1010 1520 750 52 284 8 740 680 800 0 24 6 355L FF740 2 610 120 630 254 75 140 20 67.5 355 28 730 710 655 1010 1490 750 52 284 8 740 680 800 0 24 6 FF740 4、6、8 610 120 630 254 95 170 25 86 355 28 730 710 655 1010 1520 750 52 284 8 740 680 800 0 24 6 Note: 1)R is the distance from the flange mounting surface to the shaft shoulder.

2)D dimensional tolerance: medium 19-28 is j6; Medium 38-48 is k6; Medium 55-80 is m6; Medium 95 is m6.IMB5 H80~280

Seat Number Flange No. Number of poles Dimensions mm D* E F G M N * P S T Number of Flange Holes AC L LD LA AD R 80 FF165 2、4、6、8 19 40 6 15.5 165 130 200 12 3.5 4 167 305 72 12 145 0 90S FF165 2、4、6、8 24 50 8 20 165 130 200 12 3.5 4 190 360 76 12 170 0 90L FF165 2、4、6、8 24 50 8 20 165 130 200 12 3.5 4 190 390 76 12 170 0 100L FF215 2、4、6、8 28 60 8 24 215 180 250 14.5 4 4 206 435 83 13 180 0 112M FF215 2、4、6、8 28 60 8 24 215 180 250 14.5 4 4 235 440 87 14 200 0 132S FF265 2、4、6、8 38 80 10 33 265 230 300 14.5 4 4 296 510 99 14 230 0 132M FF265 2、4、6、8 38 80 10 33 265 230 300 14.5 4 4 296 550 99 14 230 0 160M FF300 2、4、6、8 42 110 12 37 300 250 350 18.5 5 4 335 670 146 15 265 0 160L FF300 2、4、6、8 42 110 12 37 300 250 350 18.5 5 4 335 670 146 15 265 0 180M FF300 2、4、6、8 48 110 14 42.5 300 250 350 18.5 5 4 365 735 161 15 285 0 180L FF300 2、4、6、8 48 110 14 42.5 300 250 350 18.5 5 8 365 770 161 15 285 0 200L FF350 2、4、6、8 55 110 16 49 350 300 400 18.5 5 8 418 870 186 17 325 0 225S FF400 4、8 60 140 18 53 400 350 450 18.5 5 8 465 880 189 20 350 0 225M FF400 2 55 110 16 49 400 350 450 18.5 5 8 465 885 189 20 350 0 FF400 4、6、8 60 140 18 53 400 350 450 18.5 5 8 465 915 189 20 350 0 250M FF500 2 60 140 18 53 500 450 550 18.5 5 8 525 990 207 22 405 0 FF500 4、6、8 65 140 18 58 500 450 550 18.5 5 8 525 990 207 22 405 0 280S FF500 2 65 140 18 58 500 450 550 18.5 5 8 588 975 215 22 435 0 FF500 4、6、8 75 140 20 67.5 500 450 550 18.5 5 8 588 995 215 22 435 0 280M FF500 2 65 140 18 58 500 450 550 18.5 5 8 588 1015 215 22 435 0 FF500 4、6、8 75 140 20 67.5 500 450 550 18.5 5 8 588 1035 215 22 435 0 Note: 1)R is the distance from the flange mounting surface to the shaft shoulder.

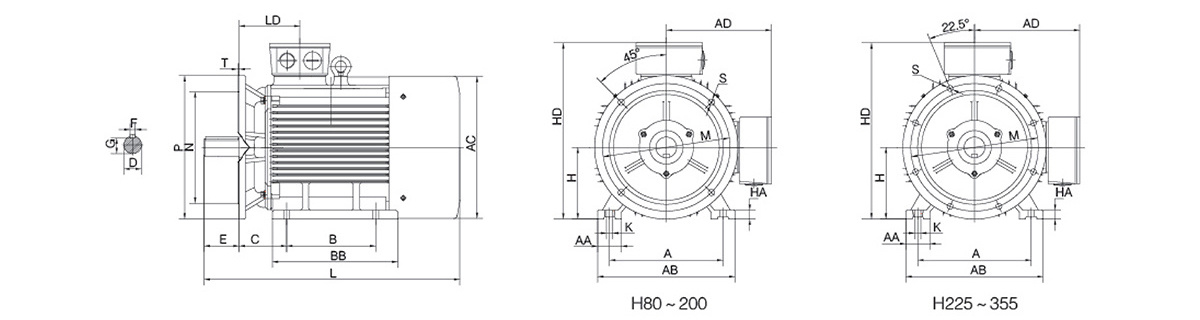

2) D dimensional tolerance: medium 19-28 is j6; Medium 38-48 is k6; Medium 55-80 is m6; Medium 95 is m6.IMB34 H80~112

Seat Number Number of poles Dimensions mm Overall dimension Number of Flange Holes A B C D E F G H K M N * P R * S T AB AC AD HD L 80 2、4、6、8 125 100 50 19 40 6 15.5 80 10 100 80 120 0 M6 3.0 165 167 145 220 305 4 90S 2、4、6、8 140 100 56 24 50 8 20 90 10 115 95 140 0 M8 3.0 180 190 170 265 360 4 90L 2、4、6、8 140 125 56 24 50 8 20 90 10 115 95 140 0 M8 3.0 180 190 170 265 390 4 100L 2、4、6、8 160 140 63 28 60 8 24 100 12 130 110 160 0 M8 3.5 205 206 180 270 435 4 112M 2、4、6、8 190 140 70 28 60 8 24 112 12 130 110 160 0 M8 3.5 230 235 200 310 440 4 Note: N dimension tolerance is j6.

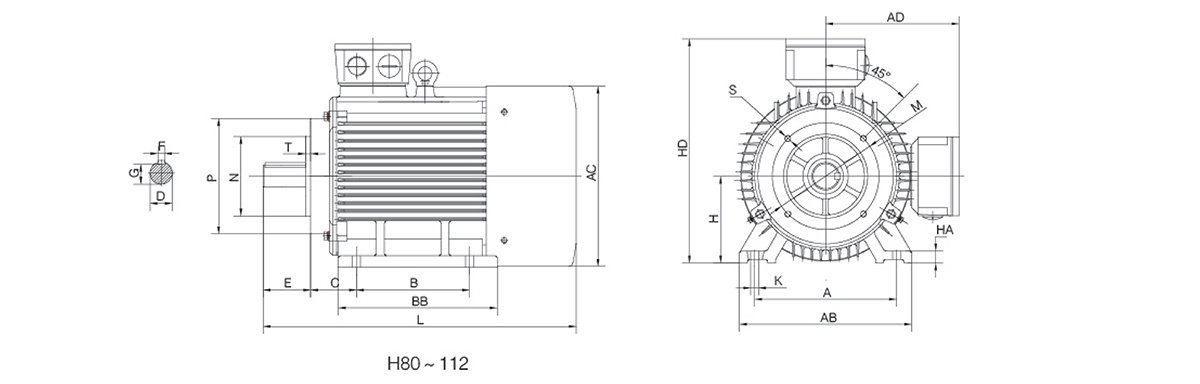

IMB14 H80~112

Seat Number Number of poles Dimensions mm Number of Flange Holes Overall dimension D* E F G M N * P R S T AC AD HF L 80 2、4、6、8 19 40 6 15.5 100 80 120 0 M6 3.0 4 167 145 - 305 90S 2、4、6、8 24 50 8 20 115 95 140 0 M8 3.0 4 190 170 - 360 90L 2、4、6、8 24 50 8 20 115 95 140 0 M8 3.0 4 190 170 - 390 100L 2、4、6、8 28 60 8 24 130 110 160 0 M8 3.5 4 206 180 245 435 112M 2、4、6、8 28 60 8 24 130 110 160 0 M8 3.5 4 235 200 275 440 IMV1 H180~355

Seat Number Number of poles Dimensions mm Number of Flange Holes Overall dimension D* E F G M N * P R S T AC AD HF L 180M 2、4、6、8 48 110 14 42.5 300 250 350 0 18.5 5 4 365 285 526 795 180L 2、4、6、8 48 110 14 42.5 300 250 350 0 18.5 5 4 365 285 526 830 200L 2、4、6、8 55 110 16 49 350 300 400 0 18.5 5 4 418 325 595 935 225S 2、4、6、8 60 140 18 53 400 350 450 0 18.5 5 8 465 350 647 975 225M 2、4、6、8 55

60140 16

1849

53400 350 450 0 18.5 5 8 465 350 647 980

1010250M 2、4、6、8 60

65140 18 53

58500 450 550 0 18.5 5 8 525 405 726 1110 280S 2、4、6、8 65

75140 18

2058

67.5500 450 550 0 18.5 5 8 588 435 820 1105

1125280M 2、4、6、8 65

75140 18

2058

67.5500 450 550 0 18.5 5 8 588 435 820 1137

1157315S 2、4、6、8 65

80140

17018

2258

71600 550 660 0 24 6 8 620 555 950 1310

1340315M 2、4、6、8 65

80140

17018

2258

71600 550 660 0 24 6 8 620 555 950 1425

1450315L 2、4、6、8 65

80140

17018

2258

71600 550 660 0 24 6 8 620 555 950 1425

1450355M 2、4、6、8 75

95140

17020

2567.5

86740 680 800 0 24 6 8 710 655 1145 1620

1640355L 2、4、6、8 75

95140

17020

2567.5

86740 680 800 0 24 6 8 710 655 1145 1620

1640Note: 1)D dimensional tolerance: medium 19-28 is j6;φ 38-48 is k6; Medium 55-80 is m6; Medium 95 is m6.

2)N dimension tolerance is j6. -

Model Power

kWSpeed

r/minEfficiency

%power factor

COSφCurrent (380V) Torque Noise

dB(A)

LwWeight

kgRated current

IN(A)Stall current Rated torque

TN (N.M)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 3000r/min YE4-63M1-2 0.18 2800 70.8 0.80 0.48 7.0 0.61 2.3 2.2 61 8 YE4-63M2-2 0.25 2800 74.3 0.81 0.63 7.0 0.85 2.3 2.2 61 8.5 YE4-71M1-2 0.37 2800 78.1 0.81 0.89 7.0 1.2 2.3 2.2 64 9.5 YE4-71M2-2 0.55 2800 81.5 0.82 1.3 7.0 1.8 2.3 2.3 64 10.5 YE4-80M1-2 0.75 2825 83.5 0.83 1.6 8.5 2.5 2.2 2.3 62 23 YE4-80M2-2 1.1 2825 85.2 0.83 2.4 8.5 3.7 2.2 2.3 62 24 YE4-90S-2 1.5 2840 86.5 0.85 3.1 9.0 5.0 2.2 2.3 67 26 YE4-90L-2 2.2 2840 88.0 0.86 4.4 9.0 7.4 2.2 2.3 67 27 YE4-100L-2 3 2880 89.1 0.87 5.9 9.5 9.9 2.2 2.3 74 41 YE4-112M-2 4 2890 90.0 0.88 7.7 9.5 13.2 2.2 2.3 77 52 YE4-132S1-2 5.5 2900 90.9 0.88 10 9.5 18.1 2.0 2.3 79 68 YE4-132S2-2 7.5 2900 91.7 0.89 14 9.5 24.7 2.0 2.3 79 76 YE4-160M1-2 11 2930 92.6 0.89 20 9.5 35.8 2.0 2.3 81 132 YE4-160M2-2 15 2930 93.3 0.89 27 9.5 48.8 2.0 2.3 81 149 YE4-160L-2 18.5 2930 93.7 0.89 34 9.5 60 2.0 2.3 81 165 YE4-180M-2 22 2940 94.0 0.89 40 9.5 71 2.0 2.3 83 230 YE4-200L1-2 30 2950 94.5 0.89 54 9.0 97 2.0 2.3 84 268 YE4-200L2-2 37 2950 94.8 0.89 67 9.0 119 2.0 2.3 84 293 YE4-225M-2 45 2970 95.0 0.89 81 9.0 144 2.0 2.3 86 341 YE4-250M-2 55 2970 95.3 0.89 99 9.0 176 2.0 2.3 89 435 YE4-280S-2 75 2970 95.6 0.89 134 8.5 241 1.8 2.3 91 566 YE4-280M-2 90 2970 95.8 0.89 160 8.5 289 1.8 2.3 91 635 YE4-315S-2 110 2980 96.0 0.89 196 8.5 352 1.8 2.3 92 936 YE4-315M-2 132 2980 96.2 0.89 234 8.5 423 1.8 2.3 92 1026 YE4-315L1-2 160 2980 96.3 0.89 284 8.5 512 1.8 2.2 92 1164 YE4-315L2-2A 185 2980 96.4 0.89 328 8.5 592 1.8 2.2 92 1200 YE4-315L2-2 200 2980 96.5 0.89 354 8.5 640 1.8 2.2 92 1222 YE4-355M1-2A 220 2985 96.5 0.89 389 8.5 703 1.6 2.2 97 1620 YE4-355M1-2 250 2985 96.5 0.91 433 8.5 799 1.6 2.2 97 1710 YE4-355M2-2 280 2985 96.5 0.91 484 8.5 895 1.6 2.2 97 1980 YE4-355L-2 315 2985 96.5 0.91 545 8.5 1007 1.6 2.2 97 2025 YE4-3551-2 355 2985 96.5 0.90 614 8.6 1135 0.9 1.8 97 2682 YE4-3552-2 375 2985 96.5 0.90 649 8.6 1199 0.9 1.8 97 2790 Model Power

kWSpeed

r/minEfficiency

%power factor

COSφCurrent (380V) Torque Noise

dB(A)

LwWeight

kgRated current

IN(A)Stall current Rated torque

TN (N.M)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 1500r/min YE4-63M1-4 0.12 1400 69.8 0.72 0.36 6.6 0.85 2.1 2.2 52 8 YE4-63M2-4 0.18 1400 74.7 0.73 0.5 6.6 1.3 2.1 2.2 52 8.5 YE4-71M1-4 0.25 1400 77.9 0.74 0.66 6.6 1.7 2.1 2.2 55 9 YE4-71M2-4 0.37 1400 81.1 0.75 0.92 6.6 2.5 2.1 2.2 55 10 YE4-80M1-4 0.55 1390 83.9 0.74 1.4 6.6 3.7 2.4 2.3 56 19 YE4-80M2-4 0.75 1390 85.7 0.74 1.8 8.5 5.1 2.3 2.3 56 22 YE4-90S-4 1.1 1400 87.2 0.75 2.6 8.5 7.5 2.3 2.3 59 29 YE4-90L-4 1.5 1400 88.2 0.76 3.4 9.0 10.2 2.3 2.3 59 35 YE4-100L1-4 2.2 1420 89.5 0.79 4.7 9.0 14.8 2.3 2.3 64 44 YE4-100L2-4 3 1420 90.4 0.80 6.3 9.5 20.1 2.3 2.3 64 50 YE4-112M-4 4 1440 91.1 0.80 8.3 9.5 26.5 2.3 2.3 65 66 YE4-132S-4 5.5 1440 91.9 0.80 11 9.5 36.4 2.0 2.3 71 79 YE4-132M-4 7.5 1440 92.6 0.81 15 9.5 49 2.0 2.3 71 97 YE4-160M-4 11 1460 93.3 0.83 22 9.5 71 2.0 2.3 73 144 YE4-160L-4 15 1460 93.9 0.84 29 9.5 98 2.0 2.3 73 162 YE4-180M-4 18.5 1470 94.2 0.85 35 9.5 120 2.0 2.3 76 207 YE4-180L-4 22 1470 94.5 0.85 42 9.5 142 2.0 2.3 76 230 YE4-200L-4 30 1480 94.9 0.85 57 9.0 194 2.0 2.3 76 293 YE4-225S-4 37 1480 95.2 0.85 69 9.0 238 2.0 2.3 78 342 YE4-225M-4 45 1480 95.4 0.85 84 9.0 290 2.0 2.3 78 377 YE4-250M-4 55 1480 95.7 0.86 102 9.0 354 2.0 2.3 79 465 YE4-280S-4 75 1480 96.0 0.87 136 8.5 483 2.0 2.3 80 750 YE4-280M-4 90 1485 96.1 0.88 162 8.5 578 2.0 2.3 80 780 YE4-315S-4 110 1485 96.3 0.89 195 8.5 707 1.8 2.2 88 944 YE4-315M-4 132 1485 96.4 0.89 234 8.5 848 1.8 2.2 88 1044 YE4-315L1-4 160 1485 96.6 0.90 280 8.5 1028 1.8 2.2 88 1142 YE4-315L2-4A 185 1485 96.6 0.90 323 8.5 1189 1.8 2.2 88 1314 YE4-315L2-4 200 1485 96.7 0.90 349 8.5 1286 1.8 2.2 88 1335 YE4-355M1-4A 220 1485 96.7 0.90 384 8.5 1414 1.8 2.2 92 1674 YE4-355M1-4 250 1490 96.7 0.90 436 8.5 1602 1.8 2.2 92 1724 YE4-355M2-4 280 1490 96.7 0.90 489 8.5 1794 1.8 2.2 92 1809 YE4-355L-4 315 1490 96.7 0.90 550 8.5 2018 1.8 2.2 92 1845 YE4-3551-4 355 1490 96.7 0.88 620 8.5 2275 0.9 1.8 92 2430 YE4-3552-4 375 1490 96.7 0.88 655 8.5 2403 0.9 1.8 92 2565 Model Power

kWSpeed

r/minEfficiency

%power factor

COSφCurrent (380V) Torque Noise

dB(A)

LwWeight

kgRated current

IN(A)Stall current Rated torque

TN (N.M)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 1000r/min YE4-71M1-6 0.18 900 70.1 0.66 0.59 7.0 2.0 1.9 2.0 52 9 YE4-71M2-6 0.25 900 74.1 0.68 0.75 7.0 2.8 1.9 2.0 52 10 YE4-80M1-6 0.37 910 78.0 0.70 1 7.0 3.8 1.9 2.0 54 19 YE4-80M2-6 0.55 910 80.9 0.72 1.4 7.0 5.7 1.9 2.1 54 20 YE4-90S-6 0.75 910 82.7 0.70 2 7.5 7.8 2.1 2.1 57 29 YE4-90L-6 1.1 910 84.5 0.70 2.8 7.5 11.5 2.1 2.1 57 36 YE4-100L-6 1.5 940 85.9 0.71 3.7 7.5 15.2 2.1 2.1 61 42 YE4-112M-6 2.2 940 87.4 0.71 5.4 7.5 22.3 2.1 2.1 65 57 YE4-132S-6 3 960 88.6 0.71 7.3 7.5 29.8 2.0 2.1 69 68 YE4-132M1-6 4 960 89.5 0.72 9.4 8.0 39.7 2.0 2.1 69 83 YE4-132M2-6 5.5 960 90.5 0.72 13 8.0 54 2.0 2.1 69 97 YE4-160M-6 7.5 970 91.3 0.76 16 8.0 73 2.0 2.1 73 160 YE4-160L-6 11 970 92.3 0.77 24 8.5 108 2.0 2.1 73 200 YE4-180L-6 15 970 92.9 0.80 31 8.5 147 2.0 2.1 73 204 YE4-200L1-6 18.5 970 93.4 0.80 38 8.5 182 2.0 2.1 73 265 YE4-200L2-6 22 970 93.7 0.81 44 8.5 216 2.0 2.1 73 284 YE4-225M-6 30 980 94.2 0.82 59 8.5 292 2.0 2.1 74 321 YE4-250M-6 37 980 94.5 0.83 72 8.5 360 2.0 2.1 76 446 YE4-280S-6 45 980 94.8 0.83 87 8.5 438 2.0 2.0 78 585 YE4-280M-6 55 980 95.1 0.84 105 8.3 535 2.0 2.0 78 684 YE4-315S-6 75 980 95.4 0.84 142 8.3 727 1.6 2.0 83 1260 YE4-315M-6 90 985 95.6 0.85 168 8.5 872 1.6 2.0 83 1300 YE4-315L1-6 110 985 95.8 0.85 205 8.5 1066 1.6 2.0 83 1350 YE4-315L2-6 132 985 96.0 0.86 243 8.0 1279 1.6 2.0 83 1400 YE4-355M1-6 160 990 96.2 0.86 294 8.0 1543 1.6 2.0 85 2100 YE4-355M2-6A 185 990 96.3 0.86 339 8.0 1784 1.6 2.0 85 2150 YE4-355M2-6 200 990 96.3 0.86 367 8.0 1929 1.6 2.0 85 2200 YE4-355L-6 250 990 96.5 0.86 458 8.0 2411 1.6 2.0 85 2290 YE4-3551-6 280 990 96.5 0.86 513 8.0 2701 1.6 2.0 91 2350 YE4-3552-6 315 990 96.6 0.82 577 8.0 3038 0.9 1.8 91 2400 YE4-3553-6 375 990 96.6 0.82 687 8.0 3617 0.9 1.8 91 2475 Model Power

kWSpeed

r/minEfficiency

%power factor

COSφCurrent (380V) Torque Noise

dB(A)

LwWeight

kgRated current

IN(A)Stall current Rated torque

TN (N.M)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 750r/min YE4-80M1-8 0.18 690 67.2 0.61 0.67 6.5 2.4 1.8 1.9 52 20 YE4-80M2-8 0.25 690 70.8 0.61 0.88 6.5 3.4 1.8 1.9 52 21 YE4-90S-8 0.37 690 74.3 0.61 1.2 6.5 5.1 1.8 1.9 56 23 YE4-90L-8 0.55 690 77.0 0.61 1.8 6.5 7.6 1.8 2.0 56 24 YE4-100L1-8 0.75 700 78.4 0.66 2.2 7.0 10 2.0 2.0 59 41 YE4-100L2-8 1.1 700 80.8 0.67 3.1 7.0 15 2.0 2.0 59 48 YE4-112M-8 1.5 700 82.6 0.69 4 7.0 20 2.0 2.0 61 59 YE4-132S-8 2.2 710 84.5 0.70 5.7 7.5 29 1.8 2.0 64 68 YE4-132M-8 3 710 85.9 0.70 7.6 7.8 40 1.8 2.0 64 90 YE4-160M1-8 4 720 87.1 0.71 9.8 7.9 53 1.8 2.0 68 149 YE4-160M2-8 5.5 720 88.3 0.72 13 8.1 72 1.8 2.0 68 176 YE4-160L-8 7.5 720 89.3 0.74 17 7.8 99 1.8 2.0 68 189 YE4-180L-8 11 730 90.4 0.74 25 7.9 143 1.8 2.0 70 204 YE4-200L-8 15 730 91.2 0.75 33 8.0 196 1.8 2.0 73 270 YE4-225S-8 18.5 730 91.7 0.75 41 8.1 242 1.8 2.0 73 297 YE4-225M-8 22 730 92.1 0.76 48 8.3 187 1.8 2.0 73 324 YE4-250M-8 30 730 92.7 0.77 64 7.9 392 1.8 2.0 75 441 YE4-280S-8 37 730 93.1 0.78 77 7.9 484 1.8 2.0 76 585 YE4-280M-8 45 740 93.4 0.78 94 7.9 580 1.8 2.0 76 675 YE4-315S-8 55 740 93.7 0.80 111 8.2 709 1.6 2.0 82 1080 YE4-315M-8 75 740 94.2 0.80 151 7.6 967 1.6 2.0 82 1134 YE4-315L1-8 90 740 94.4 0.81 179 7.7 1161 1.6 2.0 82 1215 YE4-315L2-8 110 740 94.7 0.81 218 7.7 1419 1.6 2.0 82 1314 YE4-355M1-8 132 745 94.9 0.82 258 7.7 1692 1.6 2.0 89 1980 YE4-355M2-8 160 745 95.1 0.82 312 7.7 2051 1.6 2.0 89 2025 YE4-355L-8 200 745 95.4 0.83 384 7.8 2563 1.6 2.0 89 2070 YE4-3551-8 250 745 95.4 0.83 480 7.6 3204 1.1 1.8 89 2160 YE4-3552-8 280 745 95.4 0.83 537 7.6 3589 1.1 1.8 89 2250 YE4-3553-8 315 745 95.4 0.83 604 7.6 4037 0.9 1.8 89 2340

Related Products

Message

Kindly provide valid information as below,and we will contact you as soon as possible.

Address: North of Qianyi Road, Laobagang, Hai’an, Nantong City

Technical Support: +86-15988298685

Sales Phone: +86-13813729006

After-sales service: +86-18862773030

Copyright © 2024 Nantong Senmat Electrical Machinery Co., Ltd. Business License