YBBP series explosion-proof variable frequency motor

Category:

YBBP series flameproof variable frequency speed regulation three-phase asynchronous motor is a fully enclosed, continuous working system of single-speed flameproof motor independently developed by our company, which is suitable for running in the speed regulation system powered by frequency converter. Anti-corona enameled wire is used in the motor design to adjust the electrical scheme and reduce the harmonic content, so that the motor has the advantages of energy saving, wide stepless speed range, low vibration and low noise, but also has the advantages of stable operation, no torque crawling phenomenon and long service life.

- Description

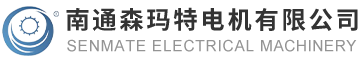

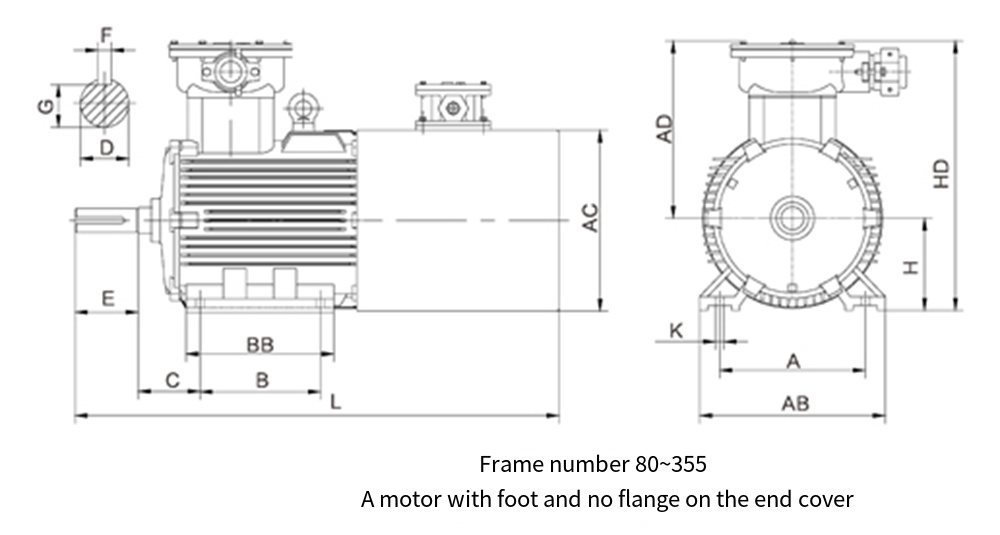

- Installation and external dimensions

- Electrical parameters

-

- Commodity name: YBBP series explosion-proof variable frequency motor

YBBP series flameproof variable frequency speed regulation three-phase asynchronous motor is a fully enclosed, continuous working system of single-speed flameproof motor independently developed by our company, which is suitable for running in the speed regulation system powered by frequency converter. Anti-corona enameled wire is used in the motor design to adjust the electrical scheme and reduce the harmonic content, so that the motor has the advantages of energy saving, wide stepless speed range, low vibration and low noise, but also has the advantages of stable operation, no torque crawling phenomenon and long service life.

YBBP series flameproof variable frequency speed regulation three-phase asynchronous motor is a fully enclosed, continuous working system of single-speed flameproof motor independently developed by our company, which is suitable for running in the speed regulation system powered by frequency converter. Anti-corona enameled wire is used in the motor design to adjust the electrical scheme and reduce the harmonic content, so that the motor has the advantages of energy saving, wide stepless speed range, low vibration and low noise, but also has the advantages of stable operation, no torque crawling phenomenon and long service life.

The motor shall be made into explosion-proof type and explosion-proof type Ex d IIBT4 Gb according to the GB3836.1-2010 and GB3836.2-2010 requirements. It is widely used to provide driving power for equipment in various frequency conversion speed regulation systems in explosive atmosphere gas places.

Motor and frequency converter supporting the use of 5-50Hz to achieve constant torque speed regulation; 50-100Hz to achieve constant power speed regulation.

Can be equipped with an independent fan, so that the motor in the entire frequency range of the cooling effect is reliable and constant.

Main performance

● Rated power range: 0.37-315kW;

● Rated frequency: 50Hz;

● Rated voltage: 380/660V;

● Number of motor poles: 2, 4, 6;

● Standard protection grade: IP55;

● Insulation system: designed according to Class F (155 ℃), the temperature rise of the motor shall be assessed at 80K during rated output and direct power supply, and the temperature rise of the 2 and 4 poles of the 315 seat number and the motor of the 355 seat number shall be allowed to reach 105K;

● Motor cooling method: the standard cooling method is IC416 forced air cooling, but when the fan load is matched and the low frequency does not exceed 30Hz, IC411 self-fan cooling type can be selected;;

● Flameproof type of motor: Ex d IIB T4 Gb;

● Motors 315-355, 200 and above 2-pole motors are equipped with grease nozzles as standard, and 160 and above motors are optional;

●Casting material: cast iron (HT250);

● Standard installation structure type: IMB3, IMB5, IMB35, etc;

● The motor can choose PTC or PT100 thermistor for winding protection, and can also be equipped with winding temperature measuring device. For motors above 160, bearing temperature measuring device can be selected;

Special design: The appearance color of the motor can be adjusted according to customer requirements.

● When the motor is adjusting speed to high frequency, attention should be paid to: if it is a fan or pump load, the power of the load will increase when the frequency becomes higher. If it exceeds the rated power of the motor, the motor will be damaged;

● When the motor running speed exceeds the rated speed, the noise and vibration value will increase, and the bearing life will be shortened; the maximum safe speed of motor operation is as follows:

Seat Number 2 Pole 4 poles 6 poles Maximum speed

r/minMaximum frequency

HzMaximum speed

r/minMaximum frequency

HzMaximum speed

r/minMaximum frequency

Hz80 5200 87 3600 120 2400 120 90 5200 87 3600 120 2400 120 100 5200 87 3600 120 2400 120 112 5200 87 2700 90 2400 120 132 4500 75 2700 90 2400 120 160 4500 75 2700 90 2400 120 180 4500 75 2700 90 2400 120 200 4500 75 2300 77 1400 70 225 3600 60 2300 77 1400 70 250 3600 60 2300 77 1400 70 280 3600 60 2300 77 1400 70 315 3600 60 2300 77 1400 70 355 3600 60 2300 77 1400 70 -

Seat Number Number of poles Installation dimensions and tolerances A B C D E F G H Basic

DimensionsBasic

DimensionsBasic

DimensionsLimit

DeviationBasic

Dimensionsroot limit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

Deviation80M 2~8 125 100 50 ±1.5 19 0.009

-0.00440 ±0.31 6 0

-0.03015.5 -0.10 80 0

-0.590S 140 56 24 50 8 0

-0.03620 0

-0.2090 90L 125 100L 160 140 63 ±2 28 60 ±0.37 24 100 112M 190 70 112 132S 216 89 38 0.018

0.00280 10 33 132 132M 178 160M 254 210 108 ±3 42 110 ±0.43 12 0

-0.04337 160 160L 254 180M 279 241 121 48 14 42.5 180 180L 279 200L 318 305 133 55 0.030

0.01116 49 200 225S 4-8 356 286 149 ±4 60 140 ±0.5 18 53 225 225M 2 311 55 110 ±0.43 16 49 4-8 60 140 ±0.5 18 53 250M 2 406 349 168 250 4~8 65 58 280S 2 457 368 190 280 0

-1.04~8 75 20 0

-0.05267.5 280M 2 419 65 18 0

-0.04358 4~8 75 20 0

-0.05267.5 315S 2 508 406 216 65 18 0

-0.04358 315 4~10 80 170 22 0

-0.05271 315M 2 457 65 140 18 0

-0.04358 4-10 80 170 22 0

-0.05271 315L 2 508 65 140 18 0

-0.04358 4-10 80 170 22 0

-0.05271 355S 2 610 500 254 75 140 20 67.5 355 4-10 95 0.035

0.013170 25 86 355M 2 560 75 0.030

0.011140 20 67.5 4-10 95 0.035

0.013170 25 86 355L 2 630 75 0.030

0.011140 20 67.5 4-10 95 0.035

0.013170 25 86

Installation dimensions and tolerances Overall dimension K M N P R S T AB AC BB HD L Basic

DimensionsLimit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

DeviationBasic

DimensionsLimit

Deviation10 0.36

0165 130 0.014

-0.011200 0 ±1.5 12 0.43

03.5 0

-0.12160 169 130 293 434 176 185 130 315 451 155 476 12 0.43

0215 180 250 ±2.0 15 4 200 209 176 340 570 240 220 180 352 664 265 230 0.016

-0.013300 275 260 190 400 634 230 664 14.5 300 250 350 ±3.0 19 0.52

05 325 317 260 474 845 302 885 350 358 310 515 928 349 1024 18.5 350 300 ±0.016 400 ±4.0 390 400 365 590 997 400 350 ±0.018 450 430 448 355 635 1034 380 1029 1059 24 0.52

0500 450 ±0.020 550 490 497 420 715 1118 540 549 440 775 1193 490 1223 28 600 550 ±0.022 660 24 6 0

-0.15630 620 570 905 1381 1411 680 1497 1527 1497 1527 740 680 ±0.025 800 735 700 640 1036 1579 1609 700 1679 1709 770 1726 1756 -

Performance Parameters at Rated Voltage 380V/50Hz

Model Power

kWSpeed

rminEfficiency

%Power

Factor

COSФCurrent (380V) Torque Rusty

LW dB(A)Rated current

IN(A)Stall current Rated torque

TN(N*m)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 3000r/min YBBP-80M1-2 0.75 2825 75.0 0.83 1.8 6.0 2.5 2.2 2.3 67 YBBP-80M2-2 1.1 2825 78.0 0.84 2.6 6.0 3.7 2.2 2.3 67 YBBP-90S-2 1.5 2840 79.0 0.84 3.4 7.0 5.0 2.2 2.3 72 YBBP-90L-2 2.2 2840 81.0 0.85 4.9 7.0 7.4 2.2 2.3 72 YBBP-100L-2 3 2880 83.0 0.87 6.3 7.0 9.9 2.2 2.3 76 YBBP-112M-2 4 2890 85.0 0.88 8.2 7.0 13.2 2.2 2.3 77 YBBP-132S1-2 5.5 2900 86.0 0.88 11.0 7.5 18.1 2.2 2.3 80 YBBP-13282-2 7.5 2900 87.0 0.88 14.9 7.5 24.7 2.2 2.3 80 YBBP-160M1-2 11 2930 88.4 0.89 21 7.5 35.8 2.2 2.4 86 YBBP-160M2-2 15 2930 89.4 0.89 29 7.5 48 2.2 2.4 86 YBBP-160L-2 18.5 2930 90.0 0.90 35 7.5 60 2.2 2.4 86 YBBP-180M-2 22 2940 90.5 0.90 41 7.5 71 2.0 2.3 89 YBBP-200L1-2 30 2950 91.4 0.90 55 7.5 97 2.0 2.3 92 YBBP-200L2-2 37 2950 92.0 0.90 68 7.5 119 2.0 2.3 92 YBBP-225M-2 45 2970 92.5 0.90 82 7.5 144 2.0 2.3 92 YBBP-250M-2 55 2970 93.0 0.90 100 7.5 176 2.1 2.3 93 YBBP-280S-2 75 2970 93.6 0.90 135 7.5 241 2.0 2.3 94 YBBP-280M-2 90 2970 93.9 0.91 160 7.5 289 2.1 2.3 94 YBBP-315S-2 110 2980 94.0 0.91 195 7.0 352 1.8 2.3 96 YBBP-315M-2 132 2980 94.5 0.91 233 7.0 423 1.8 2.3 96 YBBP-315L1-2 160 2980 94.6 0.91 282 7.0 512 1.8 2.3 99 YBBP-315L2-2 200 2980 94.8 0.92 348 7.0 640 1.8 2.3 99 YBBP-35581-2 185 2980 94.6 0.92 329 7.0 592 1.8 2.4 99 YBBP-355S2-2 200 2980 94.8 0.92 355 7.0 640 1.8 2.4 99 YBBP-355M1-2 220 2980 94.8 0.92 391 7.0 705 1.6 2.4 103 YBBP-355M2-2 250 2980 95.2 0.92 444 7.0 801 1.6 2.4 103 YBBP-355L1-2 280 2980 95.2 0.92 498 7.0 897 1.6 2.4 103 YBBP-355L2-2 315 2980 95.4 0.92 560 7.0 1009 1.6 2.4 103 Synchronous speed 1500r/min YBBP-80M1-4 0.55 1390 71.0 0.76 1.6 5.0 3.7 2.4 2.3 58 YBBP-80M2-4 0.75 1390 73.0 0.77 2.0 5.0 5.1 2.4 2.3 58 YBBP-90S-4 1.1 1400 76.2 0.78 2.9 6.0 7.5 2.3 2.3 61 YBBP-90L-4 1.5 1400 78.5 0.79 3.7 6.0 10.2 2.3 2.3 61 YBBP-100L1-4 2.2 1420 81.0 0.82 5.1 6.0 14.8 2.3 2.4 64 YBBP-100L2-4 3 1420 82.6 0.82 6.7 6.0 20.1 2.3 2.4 64 YBBP-112M-4 4 1440 84.2 0.82 8.8 6.0 26.5 2.3 2.4 65 YBBP-132S-4 5.5 1440 86.0 0.84 11.7 7.0 36.4 2.3 2.4 71 YBBP-132M-4 7.5 1440 87.0 0.85 15.6 7.0 49 2.3 2.4 71 YBBP-160M-4 11 1460 88.4 0.85 23 7.0 71 2.2 2.4 75 Performance Parameters at Rated Voltage 380V/50Hz

Model Power

kWSpeed

rminEfficiency

%Power

Factor

COSФCurrent (380V) Torque Rusty

LW dB(A)Rated current

IN(A)Stall current Rated torque

TN(N*m)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 1500r/min YBBP-160L-4 15 1460 89.4 0.85 30 7.0 98 2.2 2.4 75 YBBP-180M-4 18.5 1470 90.5 0.86 36 7.0 120 2.2 2.3 76 YBBP-180L-4 22 1470 91.2 0.86 42 7.0 142 2.2 2.3 76 YBBP-200L-4 30 1470 92.0 0.87 57 7.2 194 2.2 2.4 79 YBBP-225S-4 37 1480 92.5 0.87 71 7.2 238 2.2 2.4 81 YBBP-225M-4 45 1480 92.8 0.88 85 7.2 290 2.2 2.4 81 YBBP-250M-4 55 1480 93.0 0.88 104 7.2 354 2.2 2.4 83 YBBP-2808-4 75 1480 93.8 0.88 139 7.2 483 2.2 2.4 86 YBBP-280M-4 90 1485 94.2 0.89 167 7.2 578 2.1 2.4 86 YBBP-315S-4 110 1485 94.5 0.89 203 7.0 707 2.1 2.4 93 YBBP-315M-4 132 1485 94.8 0.89 241 7.0 848 2.1 2.4 93 YBBP-315L1-4 160 1485 94.9 0.90 291 7.0 1028 2.1 2.4 97 YBBP-315L2-4 200 1485 94.9 0.90 359 7.0 1286 2.1 2.3 97 YBBP-355S1-4 185 1488 94.9 0.90 332 7.0 1187 2.1 2.4 97 YBBP-355S2-4 200 1488 94.9 0.90 355 7.0 1283 2.1 2.3 97 YBBP-355M1-4 220 1488 95.0 0.90 391 7.0 1411 2.1 2.4 101 YBBP-355M2-4 250 1488 95.2 0.90 444 7.0 1604 2.1 2.4 101 YBBP-355L1-4 280 1488 95.2 0.90 497 7.0 1797 2.1 2.4 101 YB8P-355L2-4 315 1488 95.2 0.90 559 7.0 2021 2.1 2.4 101 Synchronous speed 1000r/min YBBP-80M1-6 0.37 910 63.0 0.70 1.3 4.0 3.8 1.9 2.1 54 YBBP-80M2-6 0.55 910 66.0 0.72 1.8 4.0 5.7 1.9 2.1 54 YBBP-90S-6 0.75 910 69.0 0.72 2.3 4.0 7.8 2.1 2.1 57 YBBP-90L-6 1.1 910 73.0 0.73 3.2 5.0 11.5 2.1 2.1 57 YBBP-100L-6 1.5 940 76.0 0.76 4.0 5.0 15.2 2.1 2.1 61 YBBP-112M-6 2.2 940 79.0 0.76 5.6 5.0 22.3 2.1 2.1 65 YBBP-1328-6 3 960 81.0 0.77 7.4 6.0 29.8 2.1 2.4 69 YBBP-132M1-6 4 960 83.0 0.78 9.9 6.0 39.7 2.1 2.4 69 YBBP-132M2-6 5.5 960 85.0 0.78 12.9 6.5 54 2.1 2.4 69 YBBP-160M-6 7.5 970 86.0 0.79 17.2 6.5 73 2.1 2.4 73 YBBP-160L-6 11 970 87.5 0.79 24 6.5 108 2.1 2.4 73 YBBP-180L-6 15 970 89.0 0.81 31.4 7.0 147 2.1 2.1 73 YBBP-200L1-6 18.5 970 90.0 0.83 37.9 7.0 182 2.2 2.4 76 YBBP-200L2-6 22 970 90.0 0.83 45 7.0 216 2.2 2.4 76 YBBP-225M-6 30 980 92.0 0.86 59 7.0 292 2.1 2.4 76 YBBP-250M-6 37 980 92.0 0.86 72 7.0 360 2.1 2.4 78 YBBP-2808-6 45 980 92.5 0.86 87 7.0 438 2.1 2.4 80 YBBP-280M-6 55 980 92.8 0.86 106 7.0 535 2.1 2.3 80 YBBP-3158-6 75 985 93.5 0.86 143 7.0 727 2.0 2.2 85 Performance Parameters at Rated Voltage 380V/50Hz

Model Power

kWSpeed

rminEfficiency

%Power

Factor

COSФCurrent (380V) Torque Rusty

LW dB(A)Rated current

IN(A)Stall current Rated torque

TN(N*m)Stall-rotor torque Maximum torque Rated current Rated torque Rated torque Synchronous speed 1000r/min YBBP-315M-6 90 985 93.8 0.86 171 7.0 872 2.0 2.2 85 YBBP-315L1-6 110 985 94.0 0.86 206 7.0 1066 2.0 2.2 85 YBBP-315L2-6 132 985 94.2 0.87 247 7.0 1279 2.0 2.2 85 YBBP-355S-6 160 985 94.5 0.88 295 7.0 1551 2.0 2.2 92 YBBP-355M1-6 185 985 94.5 0.88 340 7.0 1793 2.0 2.2 92 YBBP-355M2-6 200 985 94.5 0.88 368 7.0 1939 2.0 2.2 92 YBBP-355L1-6 220 985 94.5 0.88 404 7.0 2132 2.0 2.2 92 YBBP-355L2-6 250 985 94.5 0.88 454 7.0 2423 2.0 2.2 92 Synchronous speed 750r/min YBBP-80M1-8 0.18 710 52.0 0.61 0.9 3.3 2.42 1.8 1.9 52 YBBP-80M2-8 0.25 710 55.0 0.61 1.2 3.3 3.36 1.8 1.9 52 YBBP-90S-8 0.37 710 63.0 0.62 1.5 4.0 4.9 1.8 2.0 56 YBBP-90L-8 0.55 710 64.0 0.63 2.1 4.0 7.4 1.8 2.0 56 YBBP-100L1-8 0.75 710 71.0 0.68 2.4 4.0 10.0 1.8 2.0 59 YBBP-100L2-8 1.1 710 73.0 0.69 3.4 4.0 14.8 1.8 2.0 59 YBBP-112M-8 1.5 710 75.0 0.69 4.4 4.0 20.1 1.8 2.0 61 YBBP-132S-8 2.2 710 79.0 0.73 6.0 5.5 29.5 1.8 2.2 64 YBBP-132M-8 3 710 81.0 0.73 7.8 5.5 40 1.8 2.2 64 YBBP-160M1-8 4 720 81.0 0.73 10.3 6.0 53 1.9 2.2 68 YBBP-160M2-8 5.5 720 83.0 0.75 13.6 6.0 72 1.9 2.2 68 YBBP-160L-8 7.5 720 85.0 0.76 17.8 6.0 99 1.9 2.2 68 YBBP-180L-8 11 730 87.0 0.76 25.5 6.0 143 1.9 2.2 70 YBBP-200L-8 15 730 89.0 0.76 34.1 6.5 196 2.0 2.2 73 YBBP-225S-8 18.5 730 90.0 0.78 41.1 6.5 242 2.0 2.2 73 YBBP-225M-8 22 730 90.5 0.78 47 6.5 287 2.0 2.2 73 YBBP-250M-8 30 730 91.0 0.79 63 6.5 392 1.9 2.0 75 YBBP-280S-8 37 740 91.5 0.79 78 6.0 477 1.8 2.0 76 YBBP-280M-8 45 740 92.0 0.79 94 6.0 580 1.8 2.0 76 YBBP-3158-8 55 740 92.8 0.81 111 6.5 709 1.9 2.2 82 YBBP-315M-8 75 740 93.5 0.81 150 6.5 967 1.9 2.2 82 YBBP-315L1-8 90 740 93.8 0.82 177 6.5 1161 1.9 2.2 82 YBBP-315L2-8 110 740 94.0 0.82 217 6.5 1419 1.9 2.2 82 YBBP-3558-8 132 740 94.2 0.82 261 6.5 1703 2.0 2.2 90 YBBP-355M-8 160 740 94.2 0.82 315 6.5 2064 2.0 2.2 90 YBBP-355L1-8 185 740 94.2 0.82 364 6.5 2387 2.0 2.2 90 YBBP-355L2-8 200 740 94.5 0.83 387 6.5 2581 2.0 2.2 90 When the voltage changes, I = lza * 380/U;I-current after voltage changes; Current when la-380V; U-current voltage.

The noise is the no-load noise of the normal power supply of the motor.

Related Products

Message

Kindly provide valid information as below,and we will contact you as soon as possible.

Address: North of Qianyi Road, Laobagang, Hai’an, Nantong City

Technical Support: +86-15988298685

Sales Phone: +86-13813729006

After-sales service: +86-18862773030

Copyright © 2024 Nantong Senmat Electrical Machinery Co., Ltd. Business License